Julian Spooner

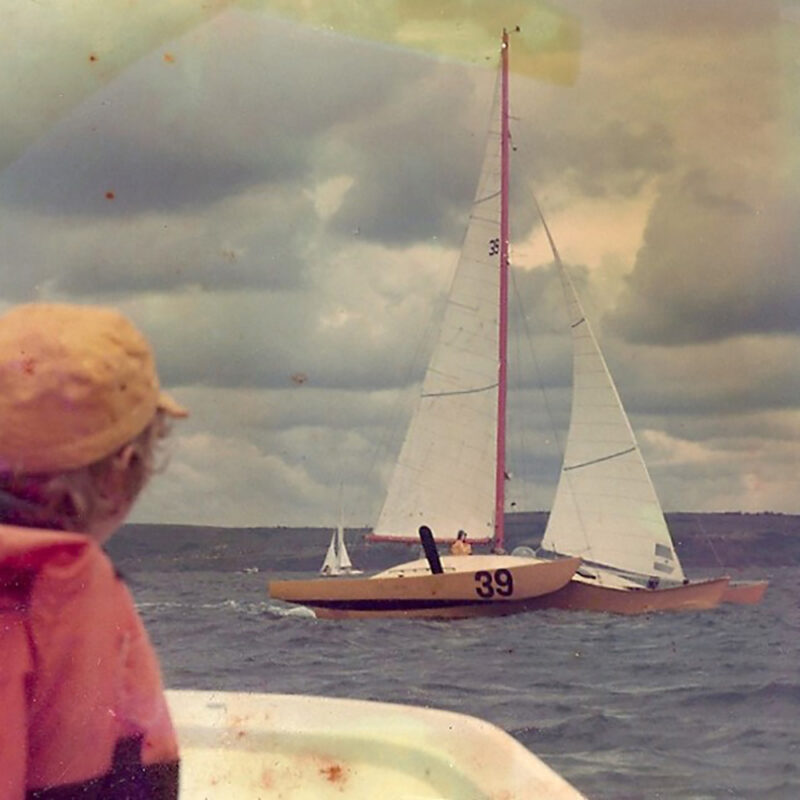

Julian grew up around the sea and boats, and a fascination with these craft and early contact with ‘high-tech’ composites has been a constant thread through his career.

Since completing a BSc in Yacht Design in 1993 he has worked extensively in the marine & composites industries in varied roles from hands-on shop floor to business management, specialising in the development and implementation of innovative composites manufacturing processes.

Working with the Advanced Composite Manufacturing Centre at the University of Plymouth, Julian jointly developed Resin Infusion processes and training courses which were delivered around the world and have had an impact on the growth of RI as a reliable and popular process especially in wind turbine blades and marine structures.

Julian worked with Princess Yachts PLC as Head of Composites, converting the company to closed moulding developing the novel process of ‘Direct Resin Infusion’ the first truly closed mould Infusion process. Also developing large scale CNC pattern making, very large heated tooling and automated fabric deposition equipment,

More recently the development of very large and light, to small and robust aircraft has been completed with a team of close collaborators.

Superconducting magnet encapsulation for Nuclear Fusion is currently an effective application of Julian’s 30 years at the forefront of composites design and manufacturing.